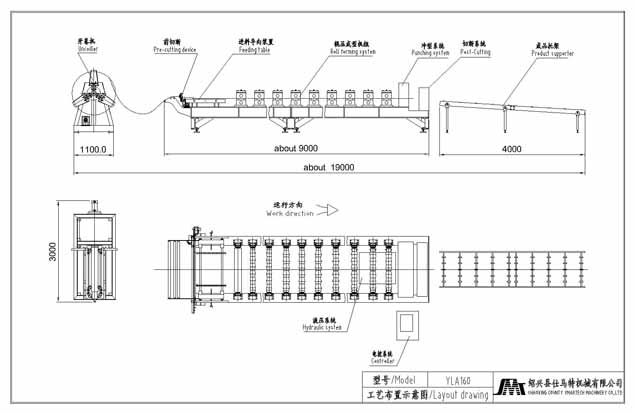

This roll forming machine is the special equipment for continuous rolling and cold-forming on steel sheet. It adopts coiling steel sheet as the raw material, decoiling, then continuous rolling and cold-forming, automatically cut to the size and output the finished panel to the supporter. The equipment adopts PLC control, AC frequency and speed adjusting technology, and it realizes the continuous automatically production, therefore, it is really a new type of energy-saving and high-effective producing equipment for steel structure.

Decoiling→Pre-cutting→ Guiding device → Roll forming →Punching →Post Cutting →Product supporter

l Main Technical Parameter

|

No

|

Item

|

Parameter

|

Remark

|

|

1

|

Suitable

Material

|

Type

|

Colored coating steel

|

The Finished products will change if using different material and thinckness.

|

|

Width(mm)

|

1220

|

|

Thickness(mm)

|

0.5-0.6

|

|

Yield Strength(Mpa)

|

230-300

|

|

2

|

Decoiler

|

ID

|

508mm

|

|

|

OD

|

1250mm

|

|

|

Capacity

|

5 Tons

|

|

|

Coil width

|

1350mm

|

|

3

|

Transmission

|

By double chains

|

|

|

4

|

Forming Speed(m/min)

|

15-20m/min

|

Not include the cut off time

|

|

5

|

Roller Material

|

No.45 steel

|

Hear treatment HRC50, hard chromized

|

|

6

|

Roller shaft

|

O.D. 80mm

|

high quality no.45 steel

|

|

7

|

Cutting Model

|

Hydraulic cutting

|

Stop the machine cutting

|

|

8

|

Cutting blade

|

Cr12 with quenched treatment HRC60-61

|

|

9

|

Finished product Length tolerance

|

±2mm

|

|

|

10

|

Power source

|

Type

|

380V/3PH/50HZ

|

customer actual requirements

|

|