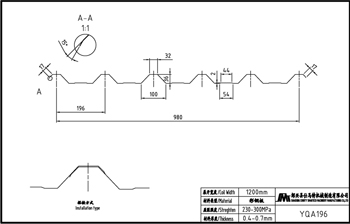

YQA196 15T电机小车纵向码垛20100601 Model (1)

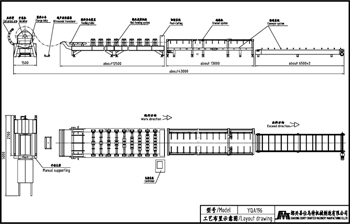

YQA196 15T电机横向码垛091115 Model (2) xThis roll forming machine is the special equipment for continuous rolling and cold-forming on steel sheet. It adopts coiling steel sheet as the raw material, decoiling, then continuous rolling and cold-forming, automatically cut to the size and output the finished panel to the supporter. The equipment adopts PLC control, AC frequency and speed adjusting technology, and it realizes the continuous automatically production, therefore, it is really a new type of energy-saving and high-effective producing equipment for steel structure.

Coil car to decoiler→Decoiling→P re-cutting→Guiding device → Roll forming →Post Cutting →Product supporter

Technical Parameters

|