Jun 30 , 2025

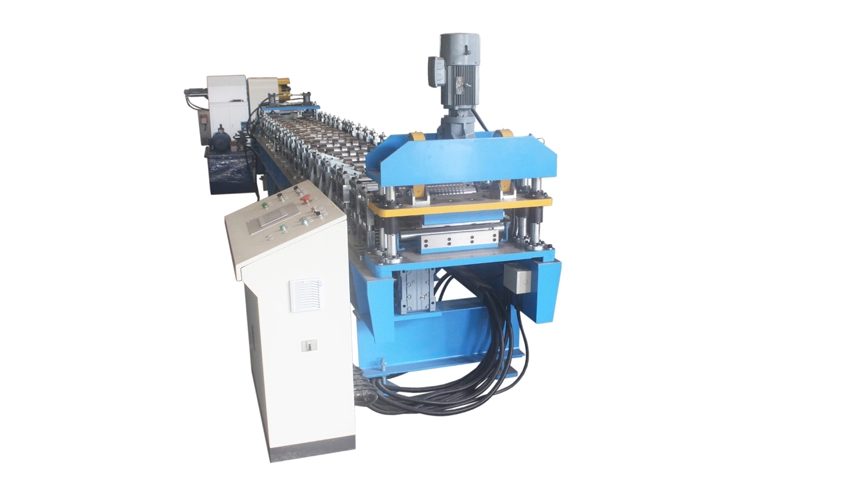

Leaky roofs damage buildings. Traditional methods fail. A standing seam roll former creates watertight, durable roofing panels that outperform conventional materials. A standing seam roll former is a specialized machine that forms metal sheets into interlocking roof panels with raised seams. These panels provide superior weatherproofing and require no exposed fasteners. Modern roofing demands innovation. Standing seam roofs dominate commercial and residential construction. These machines, provided by trusted standing seam roofing machine suppliers, have revolutionized how we protect buildings. Let's explore how they work and why they're essential.

Roof leaks cause costly repairs. Outdated methods waste time. Understanding this technology solves these problems. A standing seam roll former produces continuous metal roof panels with raised seams that interlock to prevent water penetration. The machine forms panels by passing metal through sequential shaping stations.

The Roll Forming Process Explained

The transformation from flat metal to finished panel happens in stages:

Stage | Action | Result |

Decoiling | Unwinds metal coil | Prepares raw material |

Leveling | Flattens imperfections | Ensures uniform quality |

Pre-punching | Creates connection holes | Enables panel joining |

Seam forming | Shapes interlocking edges | Creates watertight seal |

Cutting | Slices to exact length | Custom panel sizes |

The machine works at speeds up to 30 meters per minute. First, it feeds coiled metal through straightening rollers. Then, it forms the panel's cross-section progressively. Each roll station adds more definition.

The final stage creates the signature standing seam - a raised edge that interlocks with adjacent panels. This seam eliminates the need for exposed fasteners that can leak. Modern machines can form panels up to 20 inches wide with seam heights from 1-3 inches.

Modern standing seam roll forming machines aren’t just about shaping metal—they’re about automating precision and streamlining production. Here are the top features that set a high-performing roll former apart:

Adjustable panel width and seam height to accommodate different building specs

PLC (Programmable Logic Control) systems for smooth, intelligent operation

Quick-change tooling that reduces downtime when switching profiles

On-site mobility for job-site panel forming—no more transporting long panels

Hydraulic or electric cut-off units for clean, accurate panel ends

These features ensure consistency, reduce material waste, and allow your crew to produce panels that meet the highest quality standards.

Traditional roofs fail prematurely. Maintenance costs add up. Standing seam systems offer superior performance and longevity. Standing seam roofs last 50+ years, resist extreme weather, and require minimal maintenance. They're energy-efficient and recyclable, making them environmentally friendly.

The advantages extend beyond basic weatherproofing:

Performance Benefits

Feature | Advantage | Impact |

Concealed fasteners | No leak points | Eliminates water intrusion |

Thermal movement | Panels expand/contract freely | Prevents oil canning |

High wind resistance | Tested to 150+ mph | Survives hurricanes |

Fire resistance | Non-combustible material | Meets strict fire codes |

3-5x longer lifespan than asphalt

40-70% annual energy savings

95% recyclable material

Lower insurance premiums Architects favor standing seam for its clean lines. The uninterrupted surface creates a modern aesthetic. Available in various finishes, it complements any architectural style. The concealed fastener system is revolutionary. Unlike screwed-down panels, standing seams won't loosen over time. This eliminates maintenance headaches and extends service life.

Poor equipment choices hurt profits. Wrong machines create bottlenecks. Smart selection maximizes production efficiency. Consider production volume, material types, panel profiles, and automation needs when selecting a standing seam roll former that fits your business requirements. Before jumping in, ask yourself these key questions:

What materials will you run—steel, aluminum, zinc, or copper?

Do you need a fixed-line system for your facility or a portable roll former for job sites?

What panel types will your market demand—snap-lock, mechanically seamed, or batten seam?

Does the manufacturer offer technical support, training, and maintenance?

Are you building custom homes, commercial buildings, or large-scale developments?

Choosing the right machine isn’t just about specs—it’s about ensuring that your equipment supports your workflow, your clients, and your business model for the long haul.

A standing seam roll former is more than a piece of machinery—it's a scalable investment. If you're in the roofing business and want to stay competitive, especially in custom or premium markets, this tool gives you an edge. It gives you control over your quality, reduces job-site headaches, and unlocks new opportunities in both commercial and residential sectors. Whether you're producing roof panels or expanding into cladding systems, choosing equipment like a China wall panel roll forming machine from Smartech Machinery can further enhance your capabilities. As demand for energy-efficient, long-lasting roofing continues to grow, having your own roll forming capability isn't just smart—it's strategic.