Jun 25 , 2025

If you're in the metal roofing business, you know speed, precision, and consistency can make or break a project. That’s exactly where a roof rolling machine steps in. This isn’t just a piece of equipment—it’s a production powerhouse that transforms coiled metal into high-performance roofing panels with minimal effort and maximum accuracy.

Whether you’re outfitting large commercial buildings or custom residential homes, understanding how these machines work—and how to choose the right one—can elevate your business.

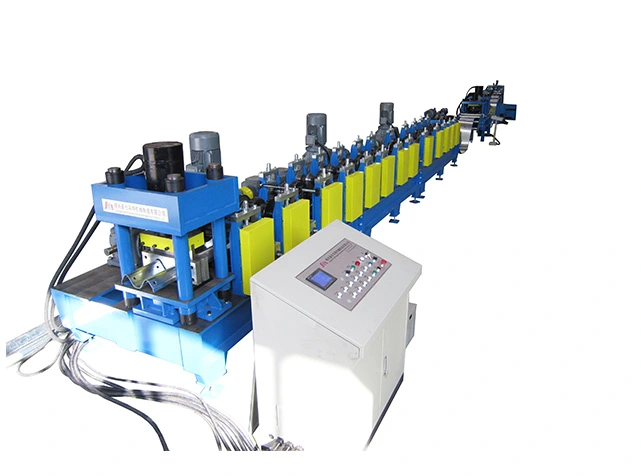

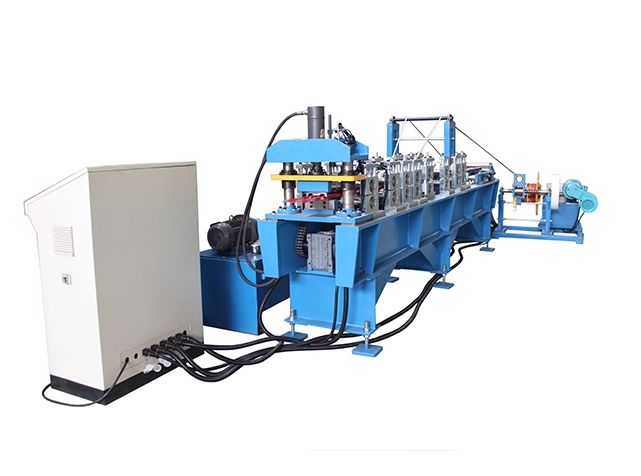

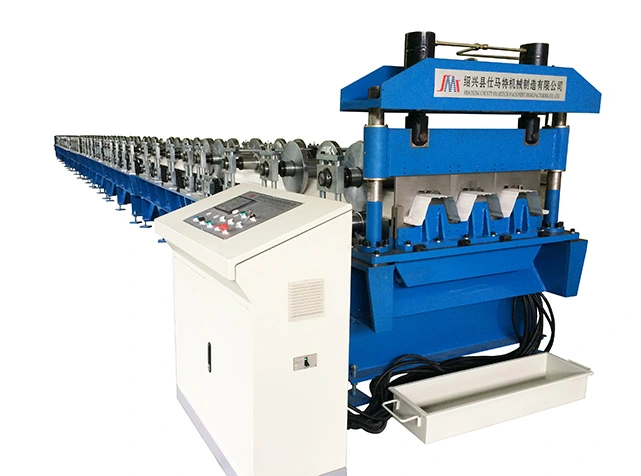

A roof rolling machine—also known as a roof panel roll forming machine—takes flat metal coil and shapes it into durable, architecturally-sound roofing panels through a series of rollers. It’s a continuous process that forms panel profiles such as standing seam, corrugated, or trapezoidal designs.

In simple terms:

You load the coil.

The machine does the rolling.

You get ready-to-install panels—cut to length, shaped precisely, and ready to go.

These machines can be installed in a factory or used on-site for jobs that require long-length panels or immediate customization.

If you’re still outsourcing panels or using manual methods, here’s why it may be time to make the switch:

Speed & Efficiency: Automated forming significantly reduces production time. Some machines can produce 20–60 meters of roofing panel per minute.

Labor Savings: One or two operators can manage the entire production process.

Panel Accuracy: Eliminate human error and guarantee consistent dimensions and seam quality.

On-Site Flexibility: Portable models allow contractors to form panels directly at the job site—ideal for long or custom-length roofing needs.

Cost Control: Minimize transportation, reduce waste, and increase project control by producing your own panels.

There’s no one-size-fits-all when it comes to roof panel forming. Choosing the right type depends on your project demands:

Standing Seam Roll Formers

For high-end residential or commercial roofing. Creates concealed-fastener systems known for clean aesthetics and water-tightness.

Trapezoidal Roll Forming Machines

Best for industrial warehouses, workshops, and metal buildings. Offers strength and weather resistance.

Corrugated Roof Roll Formers

Popular in agricultural buildings or vintage-style designs. Lightweight, cost-effective, and easy to install.

Portable Roof Roll Formers

Mobile units perfect for on-site production—reducing transport issues and saving time on custom jobs.

Buying a roof rolling machine is an investment. Ask the right questions before signing on the dotted line:

What panel profiles do you need? Snap-lock, mechanically seamed, trapezoidal, or corrugated?

What material will you use? Ensure the machine can handle your preferred coil thickness and material type (galvanized steel, aluminum, copper, etc.).

How much production capacity do you require? Think about panel length, speed, and daily volume.

Do you need a stationary or portable system? Your production environment and mobility needs will determine this.

Is there strong after-sales support? A good machine is only as good as the team backing it—look for training, parts availability, and fast technical support.

From my perspective, the metal roofing machine China made isn't just about automation—it's about control. Control over your quality, your lead times, your material waste, and ultimately, your margins. As demand grows for sleek, modern, and energy-efficient roofing systems, having your own forming equipment gives you a real edge. Partnering with industry innovators like Smartech Technologies Ltd ensures access to advanced roll forming solutions designed to meet evolving architectural and environmental standards. It’s about making your business more resilient, scalable, and competitive.