Jun 23 , 2025

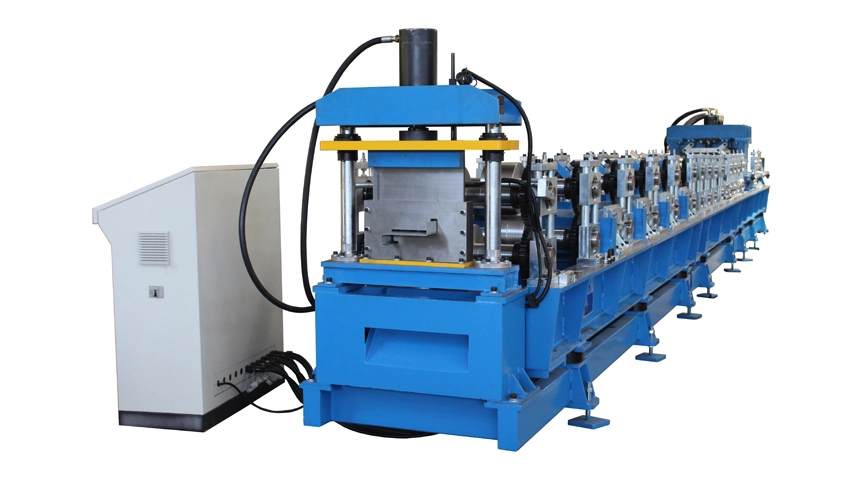

Steel structures are evolving fast—and at the heart of that evolution is a machine that doesn’t get nearly enough spotlight: the purlin roll forming machine. A purlin roll forming machine is a specialized device that continuously bends metal coils into precise purlin profiles used in construction, featuring automated operation, high output, and consistent quality control. Modern construction demands speed and reliability. These machines deliver both. Let's explore how they work and why they're transforming construction projects worldwide.

A purlin roll forming machine is engineered to manufacture structural steel purlins—those horizontal beams that support roof decking and sheeting in metal buildings. These machines are capable of producing C, Z, u purlin roll forming machine, or even Sigma profiles by shaping metal coil stock through a series of rollers, all without the need for heat or welding.

In simple terms, it takes flat steel and transforms it into a strong, uniform, and load-bearing shape—all in one smooth, automated process. The result is a purlin that’s ready for immediate installation.

Whether you’re building large-scale industrial roofs or assembling cold-formed steel frames, this machine offers a fast, precise, and scalable solution.

Quality Advantages:

Uniform strength across all purlins

Precision-engineered connections

Repeatable performance in all conditions

Operational Benefits:

Benefit | Impact |

Continuous operation | Non-stop production capability |

Automatic stacking | Simplified material handling |

Quick changeovers | Multiple profiles per shift |

Reduced manpower | 1-2 operators per machin |

The demand for steel purlins is on a sharp upward curve—and for good reason. Here are the key trends driving the market:

Prefab Construction Boom: Faster build times call for modular, standardized steel components. Purlins fit that need perfectly.

Solar Infrastructure: Steel purlins are widely used in solar racking systems, a sector seeing rapid global growth.

Cost Pressure + Labor Shortages: Manufacturers are seeking automation to maintain margins and throughput with fewer hands on deck.

Demand for Customization: Projects now require on-the-fly changes to purlin size, hole punching, and profile shape—something automated roll forming machines can handle with ease.

As the industry moves toward digital factories and real-time production tracking, roll forming machines with smart integration features (like remote diagnostics and ERP connectivity) are gaining serious traction.

Though they may look similar, beam roll forming machines and purlin roll forming machines serve very different purposes.

| Feature | Purlin Roll Forme | Beam Roll Former |

Main Output | C, Z, U, Sigma Purlins | Heavy structural I-beams or H-beams |

Material Thickness | Typically 1.2mm–3.0mm | 4.0mm and above |

Machine Design | Lighter frames, adjustable tooling | Heavier duty, more power-intensive |

End Application | Roofing support, cladding frames | Main load-bearing structure |

Flexibility | Easily switch between profiles | Less flexibility, profile-specific setups |

In short, purlin roll forming machines focus on speed and versatility, while beam roll formers are built for brute strength and heavy structural production. Choosing between the two depends entirely on what you're building.

Investing in a purlin roll forming machine isn’t just about capacity—it’s about capability. This machine doesn't just churn out steel—it creates options. The option to customize, to scale production, to respond quickly to market demands.

More importantly, as the steel construction industry leans further into automation and smart manufacturing, purlin machines that can integrate with your data systems will become standard, not optional.

If your production line still relies on manual punching, profile-specific tooling, or batch-by-batch setups, you’re not just losing time—you’re leaving money on the table.