Jan 12 , 2026

In the world of manufacturing, roll forming machines and thermoforming machines play pivotal roles in shaping materials for a majority of industrial applications. While both are used to mold and shape materials, their processes, applications, and efficiencies differ significantly. Understanding these differences is crucial for businesses looking to optimize their production lines. This article aims to shed light on what makes these machines distinct, helping industries make informed decisions on whether to invest in a roll forming machinery, metal forming machines, or a thermoforming unit.

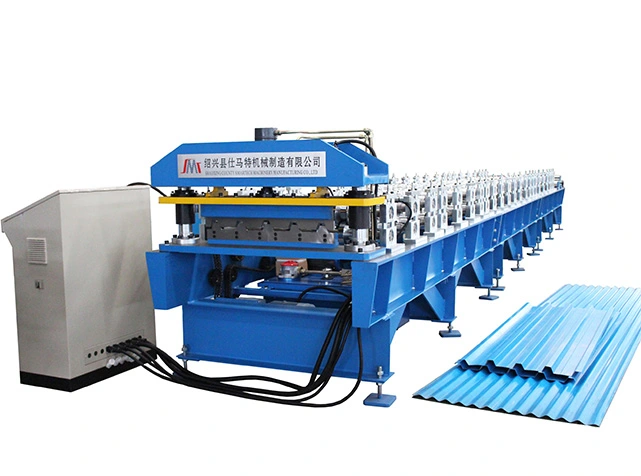

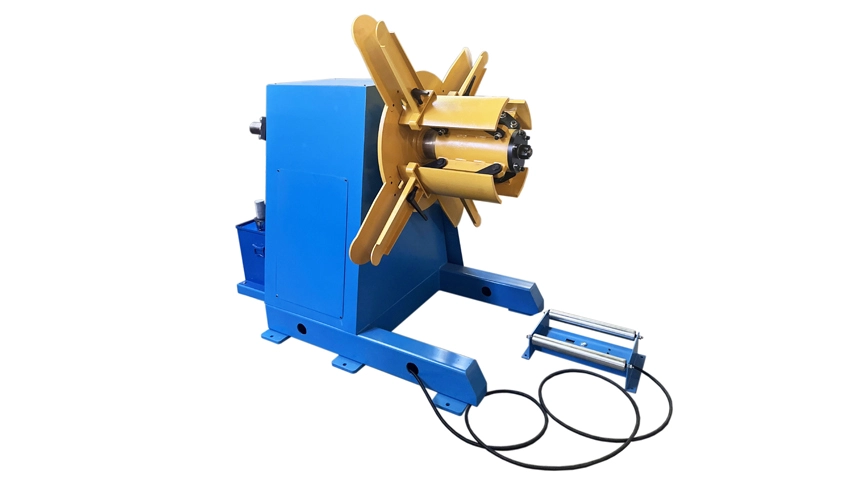

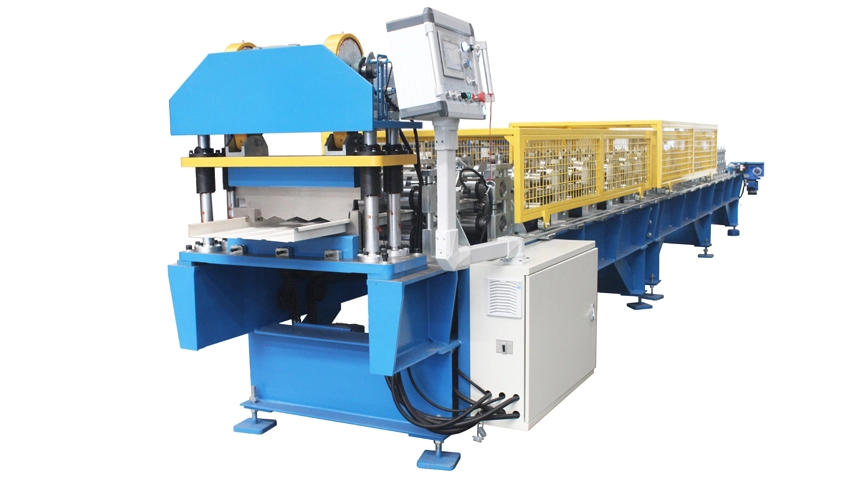

At the heart of the manufacturing process, roll forming machines and thermoforming machines utilize distinct techniques to shape materials. Roll forming machines are designed for continuous bending of a long strip of sheet metal, typically coiled steel, into a desired cross-section. The process involves unrolling, slitting, and progressively forming the material using a series of stands with roller dies. To feed the material efficiently, high-quality sheet metal decoiler is often used, ensuring smooth and continuous operation throughout the production line.

On the other hand, thermoforming involves heating a plastic sheet to a pliable temperature, forming it to a specific shape in a mold, and trimming to create a finished part. This process requires different materials, primarily thermoplastics, which offer flexibility post-heating as opposed to the rigid metals used in roll forming.

Machine Type | Material | Process |

Roll Forming Machine | Metal - Steel, Aluminum | Continuous bending using rollers |

Thermoforming Machine | Plastics - PVC, PET | Heated molding and trimming |

Cost-efficiency is a major consideration in manufacturing. Metal forming machines such as standing seam metal roof machines for sale usually involve higher initial costs due to their sophisticated, durable components like metal coil slitting machine and sheet metal decoiler. However, they can be highly cost-effective for high-volume production runs of consistently shaped metal products, like steel coils, roof panels, and gutters.

Conversely, thermoforming equipment is generally more affordable to purchase but may not be as cost-efficient for large-scale repetitive tasks given the cost and waste associated with plastics, particularly if scrap rates are high. Nevertheless, thermoforming excels in producing complex shapes with intricate details at a lower cost than more resource-intensive processes.

The industries that rely on roll forming machines are typically those that produce metal-based infrastructure. Construction and automotive sectors are heavy users of roof panel machines and metal roofing machines. Metal gutters, standing seam panels, and other structural components often start their life in a roll former machine. For companies exploring gutter machines for sale, the investment can yield consistent, high-quality products essential for building durability and safety.

In contrast, thermoforming finds applications in sectors such as packaging, medical devices, and consumer goods. The versatility of thermoforming plastics allows businesses to quickly adapt to market changes and customer preferences, producing custom packaging solutions and innovative product designs.

Each machine type offers advantages and poses challenges to manufacturers. Roll forming machines provide precision, consistency, and long-term durability vital for metals but require significant space and maintenance to operate. The extensive setup might not be economical for low-volume businesses or those needing rapid production switches.

Thermoforming, with its quick setup times and material versatility, is perfect for rapid prototyping and small production runs. However, the reliance on plastic materials raises sustainability concerns, complicating efforts to meet environmentally friendly production standards.

Deciding between a roll forming machine or a thermoforming device rests on various factors, including intended products, material preferences, budget, and long-term strategic goals. For businesses prioritizing metal product durability and consistency, investing in roll forming technology such as a coil metal forming machine or standing seam metal roof machine proves prudent.

Alternatively, companies focused on flexibility, detail, and lower upfront costs may find thermoforming equipment more suitable. Exploring both options can lead to strategic partnerships with specialized manufacturers capable of meeting diverse production needs.

Ultimately, understanding the key differences between roll forming machines and thermoforming machines empowers industries to invest in technology that aligns with their operational goals, ensuring efficient, reliable production processes.

The exploration of machine types highlights the pivotal role manufacturing machinery plays across various sectors. Whether through the precision and strength of metal roll forming machine processes or the adaptable, customizable nature of thermoformed products, the right machinery can drive significant operational improvements and product quality enhancements.