Jan 09 , 2026

When it comes to roofing options, standing seam and corrugated metal roofing machines are at the forefront for many professionals in the industry. Both types of metal roof making machine offer unique advantages, but understanding the differences in terms of design, functionality, cost, durability, and ease of installation can help you make an informed choice. This article provides a comprehensive comparison, helping you determine which roof panel machine might be a better fit for your project needs.

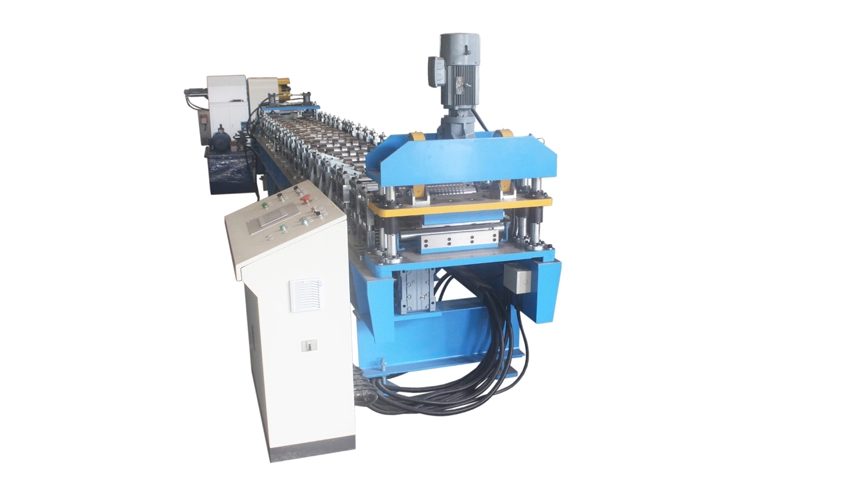

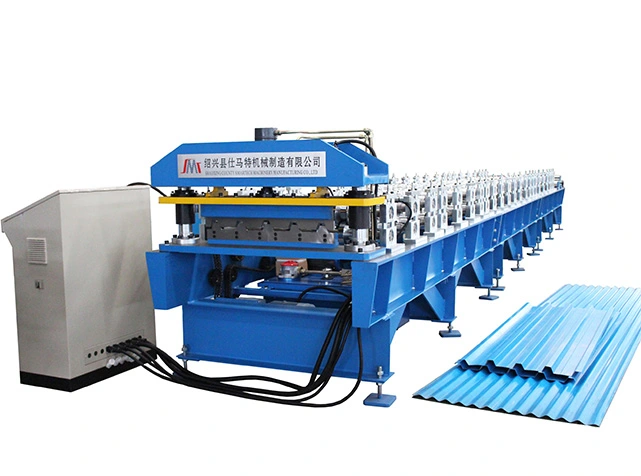

The primary distinction between standing seam and corrugated metal roofing machines lies in their design. Standing seam machines typically produce roofing panels with raised seams. These seams are fastened using clips and concealed fasteners, offering a cleaner look and reducing the risks of leaks. In contrast, corrugated metal roofing machines manufacture panels with repetitive folds (or corrugations), which enhance their strength and flexibility, often using exposed fasteners.

In recent years, demand for advanced systems such as the snap lock metal roofing machine has increased, as it combines fast installation with the sleek appearance associated with standing seam profiles, making it suitable for both residential and commercial roofing projects. For businesses looking to expand production, sourcing a corrugated roll former for sale has become a popular option to efficiently produce high-quality corrugated panels at scale.

Type | Features | Advantages |

Standing Seam Machine | Raised seams, concealed fasteners | Sleek appearance, better water shedding |

Corrugated Metal Machine | Repetitive folds, exposed fasteners | Cost-effective, stronger against impacts |

Roll forming machinery plays a crucial role in crafting these roofing panels, with roll former machines specifically designed for high precision and efficiency. Many buyers prefer sourcing equipment directly from a roof panel roll forming machine factory, as it ensures better customization, stable quality control, and long-term technical support.

Cost is a significant factor when choosing between standing seam and corrugated metal roofing machines. Typically, the initial investment in a standing seam metal roof machine is higher due to its advanced technology and materials used. However, the longevity and reduced maintenance needs can offset these costs over time.

Cost Component | Standing Seam | Corrugated Metal |

Initial Investment | High | Lower |

Maintenance | Less frequent | More frequent |

Lifetime Cost | Potentially lower | Higher due to repairs |

For contractors and manufacturers exploring options such as a standing seam metal roof machine for sale, comparing long-term value rather than just upfront pricing is essential, especially when planning large-scale or repeat production.

Durability is where standing seam models generally excel. With fewer points of penetration in the roof due to hidden fasteners, these roofs are less susceptible to leaks and possess exceptional wind resistance. Conversely, while corrugated metal roofs are also durable, their performance is heavily reliant on the quality of the installation and materials, often necessitating more frequent inspections and potential maintenance.

The performance of both types is significantly influenced by the manufacturing standards of the equipment. Many global buyers turn to suppliers of metal roofing machine China, where modern production technology and competitive pricing make large-scale manufacturing more feasible.

The installation process varies notably between these two roofing types. Standing seam roofs require precise alignment and seaming, often necessitating professional installation. However, their roofing machines, like the standing seam machine, offer automation features that reduce the complexity significantly.

On the other hand, corrugated metal roofs tend to be more installation-friendly, making them a popular choice for DIY enthusiasts. With sheet metal slitter and uncoiler tools, even a novice can efficiently handle the prep work, although professional installation is always recommended for optimal results.

Aesthetically, standing seam roofs offer a modern, streamlined look that is often preferred for residential and commercial buildings seeking a minimalist appeal. In contrast, the rustic charm of corrugated metal roofs makes them ideal for structures such as barns or sheds.

From a practical standpoint, your choice might depend on geographic and climatic considerations. For instance, environments with heavy snow or rain favor the superior drainage capabilities of the standing seam design. Conversely, the corrugations on corrugated metal panels provide enhanced structural support, vital in areas prone to heavy winds.

In conclusion, analyzing all aspects like cost, durability, installation, and aesthetics will guide you to the right choice. Whether you're considering investing in a rain gutter making machine, gutter making machine, or other gutter machines for sale, understanding these nuances ensures better decision-making for your next project.

Both standing seam and corrugated metal roofing machines have their place in modern roofing, each bringing its own advantages to different applications. For those in search of cutting-edge technology and minimal maintenance, a standing seam metal roof machine is an excellent investment. Meanwhile, those seeking cost-effectiveness and ease of installation might prefer corrugated metal machines. At the end of the day, understanding the specific requirements of your project, local climate conditions, and aesthetic preferences will help you choose the perfect roofing solution. Whether for renovation or new constructions, ensuring the right choice of metal roofing machine can lead to a successful and enduring roofing system.

For more in-depth technical specifications and guidance, you might want to explore further about roll forming machinery or consult with a roofing contractor who can provide tailored advice based on your specific needs.