Dec 19 , 2025

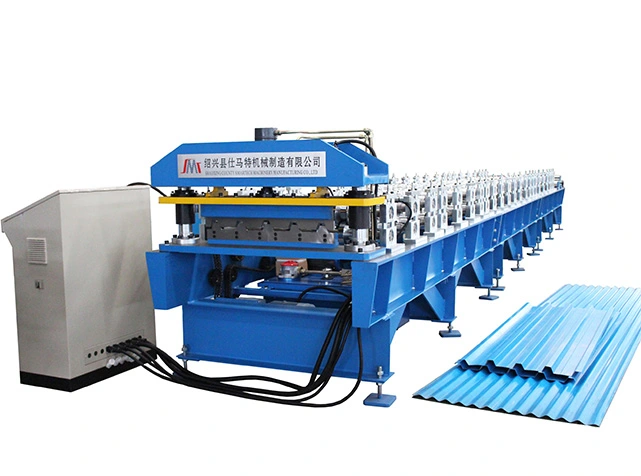

Roll forming machines are pivotal in shaping sheet metal into efficient, customizable profiles used across various industries. These machines, encompassing types like roof panel machines, gutter making machines, and metal roll forming machines, are essential for achieving precise dimensions and high-quality finishes on metal products. Understanding how to maintain these machines to extend their lifespan is crucial for ensuring continuous operation and maximizing return on investment. This article explores the expected longevity of roll forming machines, essential maintenance routines, indicators of wear and tear, upgrading components for enhanced durability, and case studies in machine durability.

The lifespan of a roll forming machine like wall sheet roll forming machine is contingent on several factors, including usage intensity, maintenance practices, and environmental conditions. On average, a well-maintained roll former can serve reliably for 15 to 20 years. Metal forming machines, such as the metal roofing machine or standing seam metal roof machine, experience wear and tear due to constant operations. However, with regular checks, these machines can exceed their expected lifespans significantly.

| Machine Type | Average Lifespan | Usage |

|---|---|---|

| Roof Panel Machine | 15-20 years | Medium to High |

| Gutter Making Machine | 10-15 years | Medium |

| Standing Seam Machine | 15-25 years | High |

Choosing the right components and following the manufacturer's guidelines can enhance longevity. Utilizing high-quality decoiler machines and uncoilers is also crucial for safeguarding the integrity of sheet metal and prolonging machine efficiency over time.

Regular maintenance is paramount to keeping roll forming machinery running efficiently and increasing its service life. Here are practical steps to ensure optimal machine health:

Lubrication: Periodic lubrication of moving parts reduces wear and friction. Using manufacturer-recommended oils can prevent breakdowns and ensure smooth operation.

Cleaning: Routine cleaning prevents metal fragments and dust from clogging the machine, which can result in mechanical failures.

Inspection: Regular inspections for signs of damage or misalignment can prevent severe issues and extend the roll forming machine’s lifespan.

Replacement of Parts: Timely replacement of worn parts, such as rollers or bearings, ensures continued precision and productivity in sheet metal processing.

Developing a maintenance schedule, including daily, weekly, and monthly tasks, can systematize these routines. Training operators on these practices is also crucial for maintaining continuity and improving machine reliability.

Recognizing early signs of wear and tear in roll forming machinery can prevent extensive damage and costly downtime. Common indicators include:

Operational Noise: Excessive noise may signify alignment issues or worn-out components.

Increased Vibration: Unusual vibrations often indicate mechanical problems that require immediate attention.

Material Output Quality: Declining quality in formed metal may suggest issues with rollers or alignment, demanding prompt calibration.

Temperature Fluctuations: Overheating can lead to component failure, making it crucial to monitor machine temperature continually.

Routine diagnostics, leveraging tools like infrared thermometers, can help identify these issues early. Operators should be encouraged to report abnormalities immediately for timely intervention.

As technology advances, upgrading roll former machine components can enhance performance, efficiency, and longevity. New technologies accommodate features like improved automation and integration with sheet metal slitter systems. Consider the following upgrades:

Advanced Automation: Integrating automated controls reduces human error and increases processing speed.

Modern Rollers: High-quality roller materials improve precision in metal shaping, reducing wear and extending machine life.

Sensor Technology: Sensors can provide real-time feedback on machine performance, enabling proactive maintenance.

Energy Efficiency: Upgrading to energy-efficient motors reduces operational costs and environmental impact.

These upgrades are investments that pay off over time by enhancing the machine’s operational efficiency and extending its service life. Consulting with metal forming machine experts can provide tailored solutions for specific needs.

Roll forming machines are vital to numerous industries, and their efficient operation is paramount for productivity. By understanding and applying best practices in maintenance, identifying signs of wear, and investing in upgrades, businesses using roll forming machinery China can maximize the lifespan and performance of these essential machines. As this article has explored, leveraging the right strategies and technologies not only extends the life of your metal forming machines but also offers a substantial return on investment in terms of efficiency and operational reliability. For more information and expert advice on maintaining your roll forming machinery, industry leaders offer consultation and support services tailored to your needs, ensuring your machinery operates at peak performance.