Jun 16 , 2025

In the ever-evolving world of construction and steel fabrication, efficiency and adaptability are everything. As demand for pre-engineered buildings (PEBs), solar mounting systems, and industrial warehouses continues to surge, so does the need for machinery that can keep up.

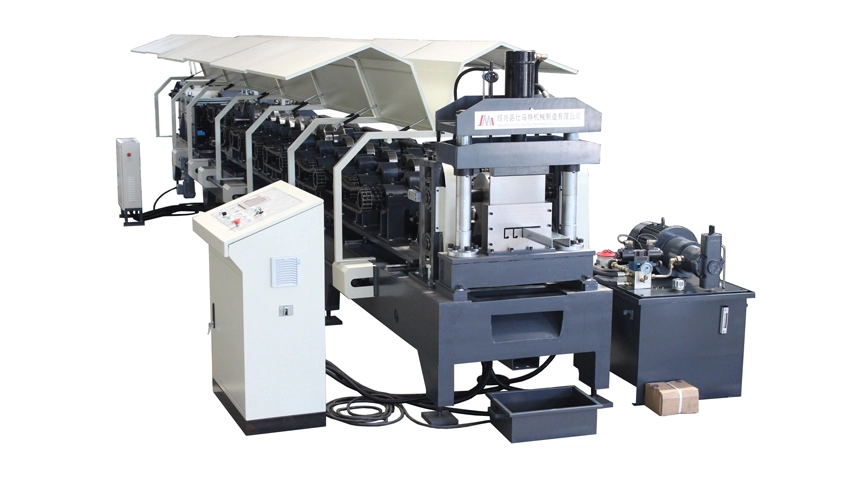

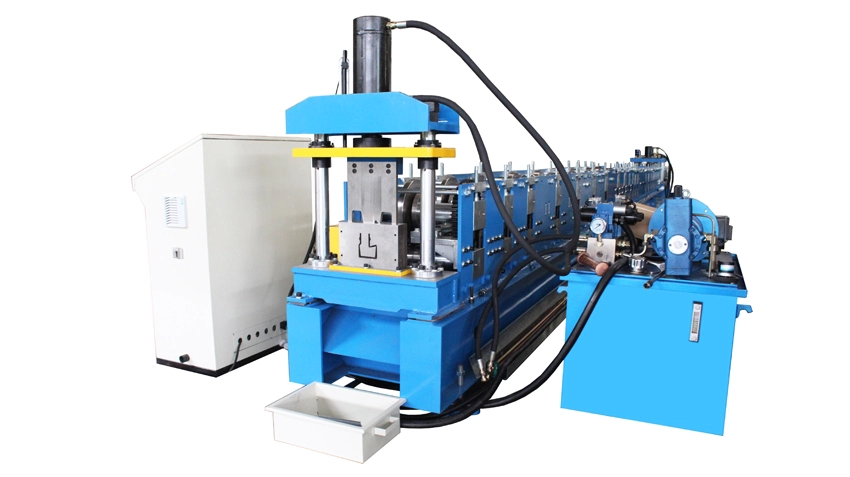

Enter the C and Z purlin machine—a smart, flexible solution that’s quickly becoming the backbone of modern steel structure production. Unlike single-profile machines, this innovative equipment enables manufacturers to produce both C and Z-shaped steel purlins using one streamlined line. That means faster production, better customization, and higher profitability.

Let’s explore why this machine is taking center stage across fabrication lines worldwide.

Traditionally, producing C and Z purlins required separate machines or time-consuming manual tooling adjustments. This process was not only inefficient but also increased labor costs and machine downtime. Today’s C/Z purlin machines offer a more intelligent alternative.

These systems are engineered to automatically switch between C and Z profiles—sometimes with the push of a button. The tooling adjusts internally, enabling seamless transitions in just minutes. This feature is ideal for factories handling:

Mixed-size production runs

Custom orders with rapid delivery timelines

Structural steel fabrication requiring multiple profile types

By integrating both functions into one line, manufacturers reduce equipment investment, save valuable floor space, and significantly boost output per shift.

No two steel structures are exactly alike—and neither are their load-bearing requirements. Architects and engineers frequently call for a range of purlin sizes and shapes to accommodate unique building spans, wind loads, and snow loads.

A quality C and Z purlin machine offers unmatched flexibility by allowing you to:

Adjust web width and flange height to specific design specs

Pre-punch holes and slots for bolt-through connections

Customize lengths for optimal nesting (especially for Z profiles)

Handle both light- and medium-gauge galvanized steel or mild steel

This makes the machine ideal for industries such as:

Agricultural and livestock buildings

Solar panel support systems

Prefabricated storage facilities

Commercial and residential steel buildings

With its wide profile range and precise forming capabilities, a C/Z purlin machine becomes a one-stop solution for any metal building supplier.

Manufacturing is no longer just about strength—it’s about smart control and digital integration.

Modern C and Z purlin lines are loaded with automation features that not only improve output quality but also reduce operator error and streamline workflows. Typical features include:

PLC + HMI touchscreen controls with programmable size settings

Automatic profile changeover systems

Hydraulic punching and shearing for burr-free, precision cuts

Real-time data feedback for production tracking and diagnostics

These systems also allow operators to store profiles as “recipes”, which means minimal downtime between orders. Many manufacturers now view this automation not as a luxury, but a necessity—especially as skilled labor becomes harder to find and customer expectations for speed and precision continue to rise.

Before choosing the right C/Z purlin machine for your business, here are some key factors to evaluate:

✔ Production Volume & Flexibility:

If you're running high volumes or frequently changing sizes, choose a model with fully automatic adjustment. If your volume is lower or size changes are rare, semi-automatic may suffice.

✔ Material Type:

What gauge and tensile strength of steel will you be processing? Ensure your machine can handle your material range with appropriate motor power and tooling strength.

✔ Profile Size Range:

Look for a machine that supports the full spectrum of C and Z purlin sizes you need—some machines can produce from 80mm up to 300mm widths or more.

✔ Support & Spare Parts:

A good machine is only as reliable as the support behind it. Choose a supplier with strong after-sales service, remote support options, and readily available replacement parts.

✔ Expandability & Integration:

Can your machine integrate with other automation systems (like stackers, packing lines, or ERP platforms)? A future-ready system ensures your investment stays relevant.

In today’s steel construction industry, manufacturers are under more pressure than ever to deliver quickly, accurately, and cost-effectively. If you're looking for a purlin roll forming machine for sale, a C and Z purlin machine is a smart investment—it doesn’t just make your production line faster, it makes it smarter. It consolidates operations, improves output consistency, and provides the flexibility to meet a wide variety of structural requirements.

Whether you're building warehouses, solar structures, or PEBs, Chinasmartech’s C and Z purlin machine gives you a competitive edge that translates directly into profit and customer satisfaction.