Jul 07 , 2025

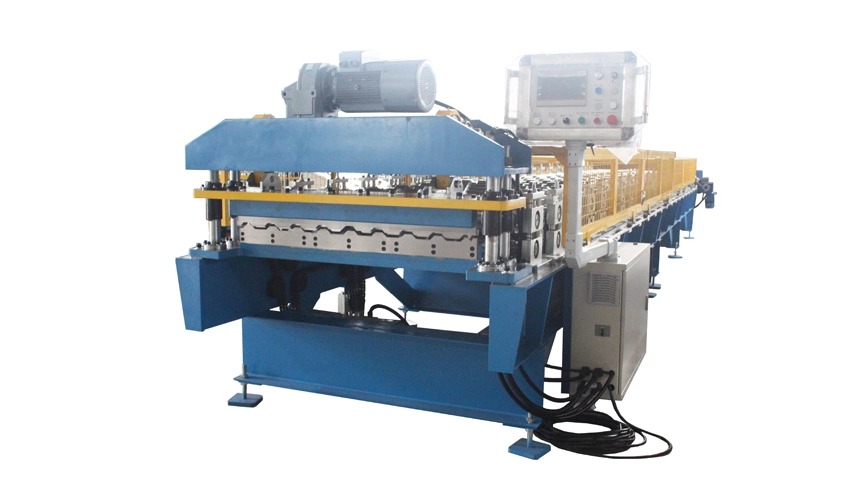

Getting metal sheets shaped into precise profiles often frustrates manufacturers. Mistakes happen. Costs add up. A trapezoidal roll forming machine solves this perfectly. A trapezoidal roll forming machine shapes metal sheets into rigid trapezoid-shaped profiles through continuous bending by roll stations. It creates uniform roof panels, partition walls, and drainage channels without welding. Metal fabrication demands precise solutions. Roll forming transforms flat coils into functional shapes. This power matters in modern construction. See how they change manufacturing below.

At its core, a trapezoidal sheet roll forming machine is a specialized piece of equipment designed to shape flat metal sheets into trapezoidal profiles. These profiles are often used in roofing and cladding systems due to their strength, durability, and clean aesthetic.

Trapezoidal roll formers combine mechanics and precision engineering. They turn raw coils into engineered products. Critical Components:

Part | Role | Impact |

Decoiler | Feeds metal coil | Enables constant operation |

Roll Stations | Gradually shape metal | Create trapezoid form without flaws |

Cutting System | Profiles to exact length | Prevents waste and secondary trimming |

Control Panel | Sets parameters | Allows easy adjustments while running |

First, the stepped roll system allows complex shapes. Rollers bend the metal little by little. Each station deepens the bend. This avoids sheet damage.

Second, they keep profiles consistent. Temperature changes won’t warp outputs. That means no waste from bends going wrong.

Third, they cut panels during the run. Saws slice lengths automatically. Workers avoid post-cutting labor. Factories save hours per batch. A typical 20-station machine can make 8-meter panels in 60 seconds.

While the setup may look intimidating at first glance, the operating principle is straightforward—cold forming through successive roll stations.

Here's a step-by-step view of the process:

1. Decoiling – The process starts with feeding a metal coil into the machine.

2. Leveling & Feeding – The sheet is straightened and fed into the rollers at a controlled speed.

3. Roll Forming – A series of precision rollers gradually bend the metal into the trapezoidal profile. Each roller station contributes to a portion of the bend, reducing stress and cracking.

4. Cutting – Once the desired length is reached, an integrated hydraulic or servo cutter slices the sheet—no need to stop the machine.

The result? High-volume, high-quality output with minimal manual intervention.

Trapezoidal roll formed sheets are a staple in modern construction. The most common applications include:

Roofing Panels – Their high strength-to-weight ratio makes them ideal for roofing systems in industrial and residential buildings.

Wall Cladding – Trapezoidal profiles provide a sleek and functional surface, capable of withstanding harsh weather conditions.

Fencing and Enclosures – Lightweight, corrosion-resistant panels are popular for boundary fencing in commercial and agricultural settings.

Cold Storage & Warehousing – The profile’s structural integrity and ease of installation make it suitable for temporary and permanent structures.

Thanks to modular design options and customizable tooling, the same machine can be adapted for different profiles and use-cases—making it a versatile asset in any production line.

As global infrastructure demands grow, so does the need for efficient, scalable production methods. Trapezoidal roll forming machines are riding this wave, driven by trends such as:

Sustainable Construction – Cold-formed steel is recyclable, lightweight, and energy-efficient—ticking all the boxes for green building projects.

Modular & Prefab Building Systems – Speed and precision are vital in prefabrication, and roll forming delivers both at scale.

Customization Demand – Clients are asking for tailored solutions—variable profiles, lengths, and coatings. Advanced roll forming machines now feature quick-change tooling and automation to meet that demand.

The market for roll forming technology, especially in Asia-Pacific and North America, continues to expand. And with the integration of IoT and smart controls, these machines are becoming even more efficient and responsive.

Having spent considerable time around roll forming lines and talking with both operators and plant managers, one thing is clear—automation is no longer optional. Today’s trapezoidal roll forming machines, including advanced China wall panel roll forming machines, aren’t just about mechanical performance. They’re part of a digital ecosystem—where speed, traceability, and zero-defect manufacturing are the new benchmarks.

Investing in a machine today isn't just about output; it's about future-proofing your production line. Look for features like remote diagnostics, real-time monitoring, and modular toolsets. These aren’t just bells and whistles—they’re the difference between scaling efficiently and being left behind.