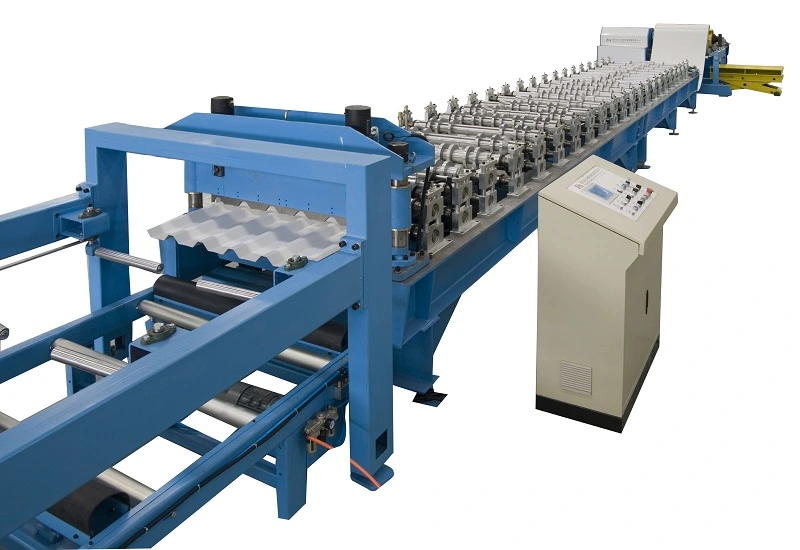

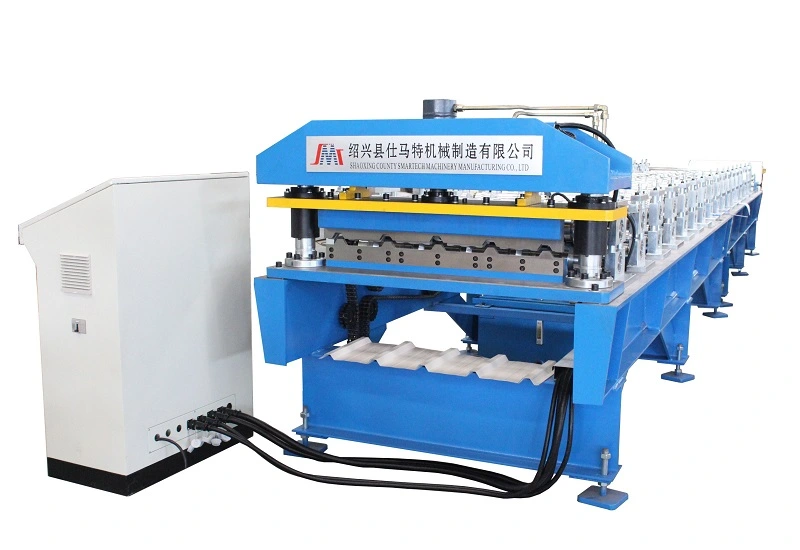

Trapezoidal sheet roll forming machine from Smartech Machinery is a full automatic metal roofing machine china and for operating the machine min. only requires one worker. Lifting the steel coil to decoiler, and then releasing the coil, feeding the coil to the main roll forming machine, setting the parameter in touch screen, turning the machine to automatic status and pressing “running” button for start working the machine automatically. The steel sheet will pass through from 1st roller station to last roller station and then cutting to the set length. The trapezoidal profile sheet from roll forming machine can be used for roofing, wall, siding, fencing and ect. Thus it is really a basic and crucial machinery for construction.

Smatech Machinery trapezoidal roof roll forming machine can produce strong metal panels that can be used for a variety of roofing and siding applications. Utilizing multiple strength ribs, the metal roofing profile offers a pleasant appearance while maintaining the strength and durability that is required on commercial applications.

Standard trapezoidal roof profile machines like C8 roll forming machine, C10 metal roof rollformer, C20 metal roof roll forming machine, C21 roofing roll forming machine,HC35 metal roofing roll former, HC44 cold roll forming machine, IBR roof sheet roll forming machine, AG panel roof machine and PBR metal roof machine are widely used machinery for constructions.

No | Item | Parameter | Remark | |

1 | Suitable Material | Type | PPGI | |

Width(mm) | 1250 | customize | ||

Thickness(mm) | 0.4-0.7 | |||

Yield Strength(Mpa) | 230-300 | customize | ||

2 | Forming Speed(m/min) | 20/30/40/50 | customize | |

3 | Roller Material | No.45 steel with Chromeplate | Up to buyer | |

4 | Roller Shaft Diameter | 80 | customize | |

5 | Cutting Model | Hydraulic/Electric Cutting | ||

6 | Power source | Type | 380V/3PH/50HZ | Up to buyer |

Total Power | According to actual design | |||

Trapezoidal Sheet Roll Forming Machine is a roll forming equipment designed specifically for building roof and wall materials. It can continuously process metal coils such as galvanized steel and color steel sheet (PPGI) into corrugated trapezoidal or double-layer deck structure roof panels. Its high-precision rolling technology ensures that the surface of the sheet is flat and the lines are clear, making it suitable for large-scale industrial production scenarios.

Excellent production capacity: The maximum production speed can reach 60 meters per minute, supporting continuous operations and significantly improving efficiency by 5.

Precision rolling system: using chrome plated 45 # steel rollers and Cr12 high-strength steel cutting blades to ensure stable plate thickness (0.3-0.8mm) and forming accuracy, with a very small tolerance range.

Flexible configuration: Supports the formation of single-layer or double-layer panels to meet different building needs (such as insulation and sound insulation double-layer structures).

Customized design: The ripple shape, board width, and color can be adjusted according to customer needs to meet personalized project requirements.

Core component strengthening: High grade forging shaft and roller design to ensure long-term stable operation of equipment; The motor cutting system reduces energy consumption and improves energy efficiency.

1. Process Mechanism

Roll Forming: A continuous process where metal coils or strips pass through a series of rotating rollers. Each roller station progressively shapes the material into a desired cross-sectional profile (e.g., trapezoidal sheets, gutters).

Bending: A localized deformation method using presses, brakes, or dies to create angles or curves at specific points on pre-cut metal sheets or bars.

2. Precision & Complexity

Roll Forming: Ideal for long, uniform profiles with consistent thickness and complex geometries (e.g., corrugated patterns). Achieves high dimensional accuracy (±0.2mm) due to incremental forming.

Bending: Suited for simple angles or curves (e.g., 90° folds). Limited in handling intricate shapes without multiple setups, risking material stress or springback.

3. Production Efficiency

Roll Forming: Enables high-speed, continuous production (up to 60m/min), minimizing material waste. Perfect for mass manufacturing of roofing sheets, panels, or structural components.

Bending: Slower, batch-oriented process requiring manual intervention. Best for small-scale or custom jobs with low-volume needs.