Jan 14 , 2026

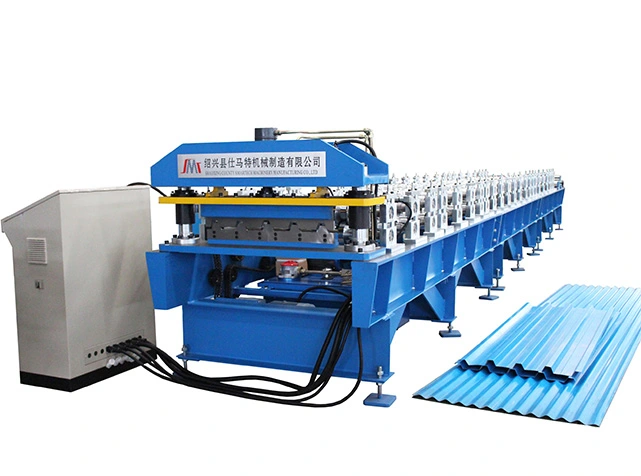

In today's rapidly evolving construction industry, the demand for efficient, portable metal roofing machines is on the rise. These machines, which include the versatile roll forming machine, metal roof machine, and slitting machine, are engineered to streamline the roofing process, offering precise cuts and seamless installations. With various models and specifications available, choosing the right metal roofing machine can be a complex task. This guide aims to illuminate the key aspects of selecting a portable metal roofing system, exploring pricing dynamics, warranty considerations, user-friendly features, and reliable supplier checks. Whether you're an industry veteran or a newcomer, understanding these factors can significantly boost your operational efficiency and bottom line.

The cost of portable metal roofing machines is influenced by various factors, including specifications, brand reputation, and additional features. High-end models may come with a premium price due to their advanced capabilities, such as automated settings and enhanced durability. On average, a quality machine roof setup might range between $10,000 to $50,000, with rain gutter making machines and downspout machines positioned in the mid to high range due to their specialized functions.

It's essential to compare specifications across models to understand what suits your project needs best. Elements like the thickness capacity, speed, and the presence of a decoiler or vertical sheet rack can substantially affect productivity. Prospective buyers looking for a roof panel machine factory can ensure consistent quality and customized production options, transforming a standard roof panel setup into a versatile system with integrated sheet metal cutting.

An attractive warranty package is paramount when investing in metal forming machinery. The typical warranty period spans one to five years, covering parts and labor. However, terms can vary significantly, so scrutinize the details. Some brands may offer extended warranties or service plans on their gutter machines for sale, which can be beneficial for long-term peace of mind.

Examine service options that accompany the purchase. Access to readily available maintenance services and technical support can prevent unnecessary downtime and enhance the lifespan of your metal roofing machine. A solid after-sales support system is a hallmark of a reliable manufacturer, demonstrating commitment to customer satisfaction and product reliability.

The usability of a roll forming machine is often a decisive factor. Machines equipped with intuitive interfaces, like touchscreens or control panels with clear indicators, minimize the learning curve and improve operational efficiency. Features such as quick setup guides or integrated diagnostic tools in a standing seam metal roof machine for sale facilitate user operation and troubleshooting.

Constructors should also look for enhancements like noise reduction technology, ergonomic designs, and safety features significant for onsite usage. A gutter forming machine with automatic feeding and cutting capabilities, or a sheet metal slitter machine for sale, not only streamlines production but also reduces manual labor, lowering error rates and enhancing safety.

Choosing the right supplier is as crucial as selecting the machine itself. Conduct thorough research on potential suppliers, prioritizing those with a robust reputation and comprehensive customer reviews. A reputable supplier should provide not just quality metal forming machines but also prompt delivery, installation support, and ongoing service options.

Utilizing accredited sources and referral recommendations can aid in identifying reliable partners. Verify certifications and memberships in industry associations as indicators of commitment to quality standards. Engaging in direct communication with suppliers can offer insights into their customer service ethos and willingness to accommodate specific needs or customization requests.

Selecting the appropriate portable metal roofing machine requires careful consideration of various factors, including model features, pricing, warranties, and supplier credibility. Investing time in research ensures that you choose a system that aligns with your operational goals and budget, ultimately enhancing productivity and quality in your projects. By prioritizing reliable suppliers and models equipped with advanced, user-friendly features, you position your venture for long-term success in the competitive landscape of construction and roofing. As the industry continues to evolve, maintaining an informed perspective on these machines will be crucial in staying ahead of the curve.