Jul 09 , 2025

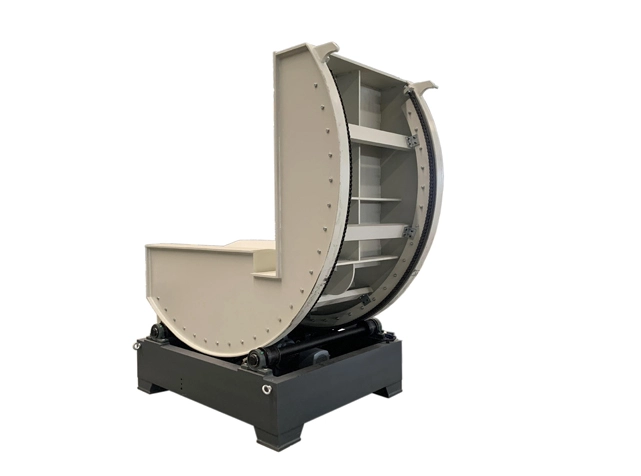

A coil upender, also known as a coil tilter or coil rotator, is a vital piece of industrial equipment designed to rotate heavy metal coils safely and efficiently. These machines are commonly used in industries like steel processing, automotive manufacturing, and metal fabrication, where large, heavy coils need to be turned from a horizontal to vertical position—or vice versa—for further handling, processing, or transport.

Whether hydraulic, mechanical, or electric, coil upenders streamline the workflow and reduce the physical strain and risk associated with manual coil handling. But beyond their basic function, coil upenders engineered by top coil upender manufacturers offer hidden advantages—such as customizable tilt angles, integrated safety interlocks, and minimal maintenance requirements—that make them indispensable in modern production environments.

While most professionals understand the basic purpose of a coil upender, many overlook the strategic advantages these machines bring to a production line:

Reduced Downtime: Manual turning of coils is time-consuming and prone to delays. A coil upender can complete the task in minutes, keeping your line running smoothly.

Product Integrity: Mishandled coils often suffer dents or surface damage. A coil upender secures the coil during rotation, preserving material quality.

Streamlined Workflow: With seamless integration into existing handling systems, coil upenders reduce the number of steps required to process coils, making the entire line more efficient.

Versatility: Many coil upenders can be customized to handle various coil sizes, materials, and weights, making them suitable for multiple applications.

By improving speed and reducing damage, coil upenders ultimately enhance production output and profitability.

Workplace safety is not only a moral responsibility but also a financial priority. Improper handling of heavy coils can lead to serious injuries, equipment damage, and costly downtime.

Here’s how coil upenders make a difference:

Enhanced Safety: They eliminate the need for cranes or manual labor to turn coils, reducing the risk of accidents and injuries.

Lower Insurance Costs: A safer working environment often translates into lower premiums for workers' compensation and liability insurance.

Reduced Labor Expenses: With automated or semi-automated models, fewer workers are needed for coil handling tasks, freeing staff for more skilled jobs.

Minimized Equipment Wear and Tear: Smooth, controlled turning reduces stress on forklifts, cranes, and other material handling systems.

In short, a coil upender is an investment that pays off—not just in safety, but in long-term operational savings.

Not all coil upenders are created equal. Selecting the right one depends on your specific operational needs. Key factors to consider include:

Weight Capacity: Ensure the upender can safely handle your heaviest coils, typically ranging from 5 to 30 tons.

Turning Angle and Speed: Some models offer full 180° rotation with adjustable speeds for different materials and processes.

Automation Level: Choose between manual, semi-automatic, and fully automated systems based on your desired efficiency and budget.

Footprint and Layout: Consider space constraints in your facility and select an upender that integrates well into your production line.

After-Sales Support: Look for reliable manufacturers who offer training, maintenance, and replacement parts.

Making the right choice ensures long-term reliability, operator safety, and a solid return on investment.

A coil upender might seem like a simple tool, but its impact on efficiency, safety, and cost control is far from ordinary. If your production line involves frequent coil handling, investing in the right upender is not just smart—it’s essential.

At Smartech Machinery, we believe that efficiency begins with intelligent handling. Our coil upender solutions are engineered not just to rotate heavy coils—but to transform your workflow. By integrating high-precision movement, compact structure, and operator-safe design, our upenders help manufacturers reduce downtime, lower labor risk, and protect material integrity. In an industry where every second counts, a reliable coil upender isn’t just equipment—it’s a productivity partner.