Jul 11 , 2025

Gone are the days of sprawling warehouses devouring real estate and manpower. The future is vertical, automated, and shockingly efficient. Let’s unpack why AVSS isn’t just an upgrade—it’s a complete reset for how we think about storage.

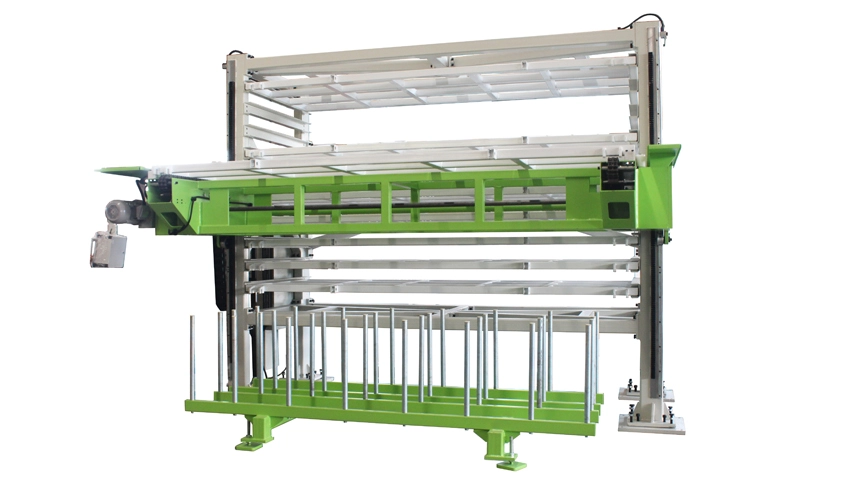

Imagine a high-density, robotic vending machine for pallets, bins, or tools. An Automatic Vertical Storage System (AVSS) uses automated lifts and retrievers to store items in vertical towers, often reaching heights of 10–30 meters. Unlike traditional shelving, AVSS requires minimal aisle space, uses ceiling height instead of floor area, and delivers items directly to operators with the push of a button. It’s software-driven inventory on autopilot—maximizing cube space while slashing human travel time.

Vertical systems aren’t just space-savers—they’re sustainability powerhouses:

Reduced Footprint: By utilizing vertical air space, facilities need 60–80% less floor area, shrinking land use and construction impacts.

Energy Efficiency: LED lighting only activates in accessed modules, and automated systems cut forklift traffic (and emissions) by 90%+.

Longer Lifespan: Durable, enclosed designs minimize equipment wear and material waste vs. traditional racking.

Lower Carbon Logistics: Smaller warehouses mean shorter transport routes for staff and goods, trimming Scope 3 emissions.

While all warehousing gains from AVSS, these sectors see transformative ROI:

Aerospace & Automotive: Securely store high-value, bulky parts (e.g., turbine blades, transmissions) with traceability.

Pharma & Healthcare: Climate-controlled vertical units ensure compliance for sensitive medications with audit-ready tracking.

Retail/E-Commerce: Handle SKU explosions for small items (electronics, cosmetics) with rapid, error-free order picking.

MRO (Maintenance, Repair, Operations): Organize tools, spare parts, and safety gear with 24/7 secure access.

Three seismic shifts are driving AVSS adoption:

Land & Labor Costs: Urban warehouse space is prohibitively expensive; AVSS delivers 3–5x more storage per square meter.

AI Integration: Modern AVSS syncs with WMS/ERP systems, using predictive analytics to slot fast-movers optimally.

Accuracy Demands: With e-commerce returns averaging 30%, zero-mistake retrieval isn’t optional—it’s economic survival.

At Smartech Machinery, we’ve seen firsthand how the automatic vertical storage system is transforming the way manufacturers handle materials. In today’s fast-paced production environments, floor space is more valuable than ever, and manual handling is both risky and inefficient. By integrating vertical storage into our clients’ workflows, we help them reclaim floor space, improve picking speed, and significantly reduce the risk of workplace injuries. What’s more, the automation brings a new level of inventory control and accuracy that manual racking simply can’t match. For us, this isn’t just a storage solution — it’s a smarter, safer, and more scalable future for industrial logistics.