Dec 24 , 2025

In the world of metal fabrication, roll forming machines play a crucial role in shaping materials for countless applications. From creating metal roofs to forming intricate steel components for industrial use, these machines have revolutionized the production process. Understanding how roll forming machines work can offer insights into their efficiency and the quality of the final products. This article will explore the basic principles of roll forming, the key components involved, common materials used, and the advantages of roll forming over traditional methods. Whether you're interested in finding a roll forming machine for sale, sourcing equipment from roll forming machine manufacturers in China, or simply curious about the technology, this guide provides valuable knowledge about these engineering marvels.

Roll forming is a continuous bending operation in which a long strip of metal, typically coiled steel, passes through several sets of rollers at room temperature. These rollers are set up in a specific sequence to gradually shape the metal into the desired profile. The process is widely applied in the manufacturing of automotive parts, building materials, and appliances. The primary advantage of roll forming is its ability to produce complex cross-sections with tight tolerances and smooth finishes.Each station in a roll forming machine performs incremental parts of the bending process, until the desired profile is obtained. The key to successful roll forming is the precise arrangement of rolls which determine the machine’s versatility and the quality of the profiles produced. This precision makes roll forming ideal for large-volume production tasks involving high-strength materials.

| Stages | Process | Output |

|---|---|---|

| Entry | Material is fed into the machine | Straight metal sheet |

| Forming | Gradual bending through rollers | Shaped profile |

| Cutting | Precision cutting into sections | Finished product |

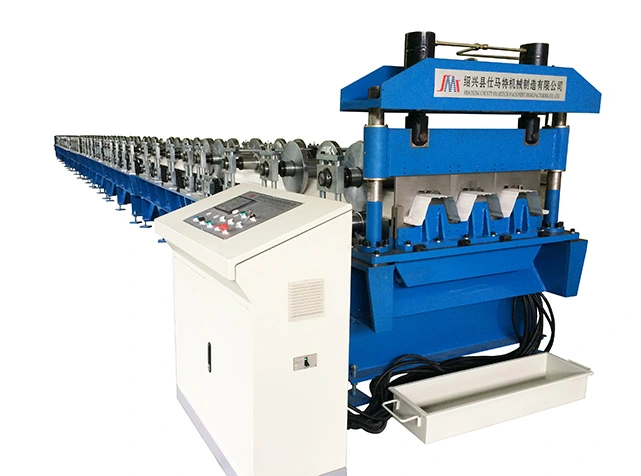

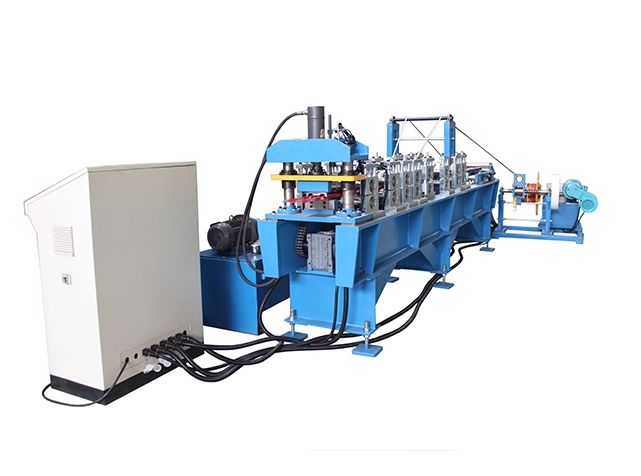

Understanding the components of a metal roll forming machine such as metal slitter machine for sale is crucial for maintenance, efficiency, and effectiveness in production. These components work together to transform metal sheets into precise shapes. The main parts of the machine include:

Uncoiler: Holds and unwinds the coil of metal sheet, feeding it continuously into the roll former.

Rolls: A series of them guides and bends the metal sheet into the desired shape through progressive bending.

Cutting Press: Once the metal is formed into the required shape, it is cut to length.

Control System: This manages the operation of the machine, ensuring precision and quality in the production line.

Each of these components must be carefully maintained and calibrated to produce high-quality parts. A robust control system enhances productivity by streamlining operations and minimizing errors, particularly when working with tough and durable metals.

The success of roll forming not only relies on the machinery but also on the materials selected for the process. Metals commonly used in roll forming include steel, aluminum, and copper. These materials are chosen for their ductility, strength, and versatility. They must be able to sustain the stresses of bending without cracking or losing structural integrity.Steel, particularly galvanized steel, is one of the most common materials, valued for its strength and corrosion resistance. Aluminum is used for its lightweight and corrosion-resistant properties, making it ideal for aerospace and automotive applications. Copper, though less frequently used, offers excellent conductivity and is sometimes chosen for electrical applications.

Roll forming provides like cz purlin roll forming machine for sale several advantages over traditional metal forming methods such as stamping, machining, or bending. These advantages include:

Efficiency: Roll forming can produce consistent, high-quality products in a continuous process that minimizes material waste and speeds up production.

Complex Shapes: The process is capable of creating complex profiles with intricate designs that would be difficult or impossible to achieve with other methods.

Consistency: Due to its continuous nature, roll forming ensures uniformity across large production batches.

Cost-Effectiveness: The process reduces material waste, energy consumption, and labor compared to other forming methods.

These benefits make roll forming a preferred choice in industries that require large-scale metal production with high precision and reliability.

Roll forming is implemented in various industries due to its efficiency and versatility. In the construction industry, roll forming machines produce metal roofing and siding, as well as components for bridges and structural supports. In the automotive industry, roll forming is used for creating body panels and structural components.Furthermore, gutter forming machines are specialized roll formers that produce gutters and downspouts efficiently, which are essential components for modern buildings. These machines, along with roof panel machines and standing seam machines, allow for rapid production of specific construction materials without compromising on quality.The scope of roll forming continues to grow as more innovations are made in machine technology and material processing, making it an indispensable process for modern manufacturing.

Roll forming machines have revolutionized metal fabrication, offering a seamless blend of precision, efficiency, and versatility. By understanding the principles, components, materials, and advantages of roll forming, industries can better harness these machines’ potential, leading to improved product quality and reduced production costs. Whether you’re looking to buy a metal roof forming machine for sale or explore advanced roll forming machinery, understanding these concepts is key to making informed decisions in the market.With the continuous advancements in technology, roll forming will undoubtedly continue to evolve, offering even more sophisticated solutions that cater to the changing demands of various industries.