Dec 26 , 2025

The acquisition of a roll forming machine represents a significant investment for businesses involved in metalworking and manufacturing. From metal roof making machines to gutter making machines, these advanced pieces of equipment are central to efficient production and quality output. However, potential buyers must understand the diverse variables contributing to their price. This article will dissect the cost factors linked with roll forming machines, explore budget-friendly options for small enterprises, evaluate long-term ROI, and detail vendor financing plans. Whether you seek a metal roof forming machine for sale or to understand mechanisms like slitting machines, this comprehensive guide is engineered for decision-makers keen to maximize equipment value.

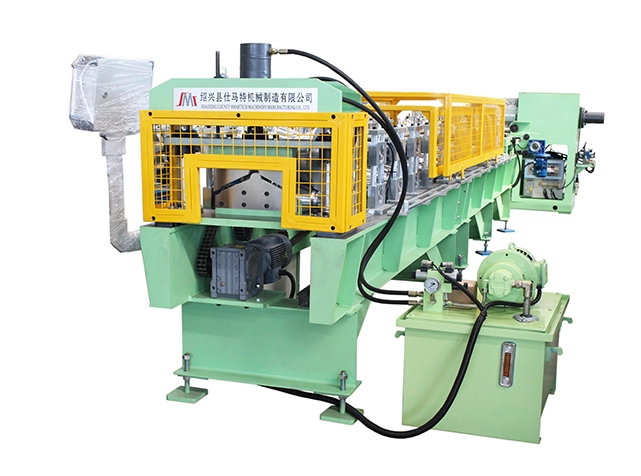

At the heart of understanding the costs associated with roll forming machinery is discerning its specific components and configurations. These machines are generally priced based on several core elements that determine their functionality and efficiency.

| Component | Role | Cost Influence |

|---|---|---|

| Frame Structure | Support framework | Material and design intricacy |

| Forming Stations | Shapes the metal | Number of stations |

| Drive System | Powers the machine | Motor power and efficiency |

| Control System | Operates functionalities | Automation level |

These components can each dictate the overall cost. The frame structure is essential for housing and supporting the forming stations and can vary based on whether the base material is aluminum or steel. More forming stations generally mean a higher price due to increased production capabilities. The drive system, including the motor's size and efficiency, directly impacts operational costs. Finally, the extent of automation in the control system—from basic setups to fully computerized interfaces—affects pricing.

While basic pricing components set the foundation, numerous external factors can influence the costs of metal forming machines. These include:

Customization: Machines tailored for specific tasks, like gutter forming machines or roof panel machines, tend to cost more due to the specialized tooling and dies required.

Technological Features: Advanced technologies like remote monitoring, automatic adjustments, and integrated diagnostics can add to the price but enhance long-term production efficiency.

Brand and Manufacturer Reputation: Brands known for high-quality roll former machines might charge a premium based on their reliability and customer service reputation.

Market Conditions: Supply chain fluctuations, raw material prices, and economic conditions can also affect pricing.

Understanding these influencers allows businesses to align their investments with operational needs effectively, ensuring that they purchase machines that optimize their production capabilities without overspending.

For smaller businesses or startups, the cost of a new metal roof machine like metal deck roll forming machine might be prohibitive. However, several strategies can help mitigate these costs:

Used Equipment: Purchasing pre-owned machines can offer significant savings and, with proper inspection, still provide reliable performance.

Basic Models: Choosing models with fewer automation features or a reduced number of forming stations can lower upfront costs without entirely sacrificing functionality.

Modular Upgrades: Selecting a machine capable of being upgraded in stages allows for spreading out the investment over time as production demands grow.

Leasing and Rent-to-Own: These options provide flexibility and minimize initial cash outlays, allowing businesses to use advanced machines with manageable monthly payments.

Budget optimization also involves a thorough understanding of the specific needs for projects, which might include equipment like gutter machines for sale or decoiler machine setups. Thus, strategically aligning budget constraints with functional business requirements is crucial for achieving cost efficiency.

Investing in a standing seam metal roof machine or equivalent equipment must be assessed through the lens of return on investment (ROI). A comprehensive ROI analysis not only validates the investment but can also reveal opportunities for profit maximization. Key components include:

Efficiency Gains: Automated machines can drastically reduce labor costs and waste, enhancing production speed and output quality.

Product Flexibility: Machines that accommodate a variety of products, from rain gutter making machines to sheet metal slitters, expand business offerings and market agility.

Maintenance Costs: Choosing high-quality, robust machines helps in lowering maintenance expenses and reducing downtime, which can significantly alter ROI calculations.

Scalability: Equipment designed with scalability allows businesses to respond efficiently to market demands, enhancing long-term profitability.

In terms of financial health, understanding how investing in roll forming machinery translates into higher profits ensures the strategic growth of the business.

Given the high upfront cost of a downspout machine or vertical sheet rack, vendor financing can offer a path to acquisition that aligns with cash flow constraints. Here’s how it can benefit businesses:

Low Initial Investment: By spreading payments over a period, businesses can retain more working capital and leverage it for other operational needs.

Structured Payments: Flexible payment plans that align with revenue cycles can ease cash flow stress.

Credit Building: Consistent payment can enhance a business’s credit profile, aiding in future financial services access.

Concessionary Rates: Some vendors offer attractive interest rates for financing, further reducing the cost burden.

Vendor financing solutions must be evaluated carefully to ensure they align with business goals and overall financial health. By using these financing options wisely, businesses can invest in essential equipment such as a metal processing machine, roofing machine, or uncoiler while maintaining long-term financial stability.

Understanding the complexities and variables affecting the costs of roll forming machinery is crucial for businesses aiming to make informed purchasing decisions. Whether you’re exploring options for a metal roll forming machine or looking into gutter forming machines, understanding pricing components, external influences, budget strategies, ROI potential, and vendor financing can provide a robust framework for decision-making. As manufacturing technologies evolve, staying informed and strategically aligning business objectives with equipment capabilities can optimize resources and propel industrial growth.

For further reading, please refer to our related resources section below.