Jun 20 , 2025

In today's fast-paced manufacturing environment, efficiency starts at the very first station of your production line—the decoiler. Whether you’re operating a roll forming line, stamping press, or laser cutter, a reliable decoiler ensures smooth, continuous feeding of metal coils, laying the foundation for consistent output and minimal downtime. In this guide, we’ll walk you through what decoilers do, how to choose the right type, and how to keep your equipment running safely and efficiently. Along the way, we’ll also touch on related equipment and suppliers—such as coil upender manufacturers—that often play a crucial role in material handling and processing workflows.

A decoiler is much more than just a mechanical stand. It’s a critical automation tool that feeds coil material into your production line at a regulated pace. Without a decoiler, operators would have to manually feed material—wasting time, introducing inconsistencies, and risking safety.

Here’s why decoilers are indispensable:

Seamless Material Handling: They unroll heavy coils smoothly, maintaining consistent tension and speed.

Improved Workflow: Continuous feeding eliminates frequent stops and increases line efficiency.

Reduced Material Waste: Controlled decoiling minimizes scratching, buckling, and overfeeding.

Operator Safety: Automation reduces direct handling of heavy coils, minimizing injuries and fatigue.

Whether you’re producing roofing sheets, C/Z purlins, or automotive components, a decoiler ensures that the rest of your line performs at its best.

Selecting the right decoiler depends on your production needs, material specs, and level of automation. Here’s a breakdown of the most common types:

1. Manual Decoilers

Basic, low-cost solution for small-scale or low-volume operations.

Coil feeding is manual, with limited tension control.

Suitable for light materials and simple forming lines.

2. Motorized Decoilers

Equipped with motors to rotate the coil at controlled speeds.

Ideal for mid-volume operations where precision and speed are required.

Often used with a loop control system to sync with downstream machinery.

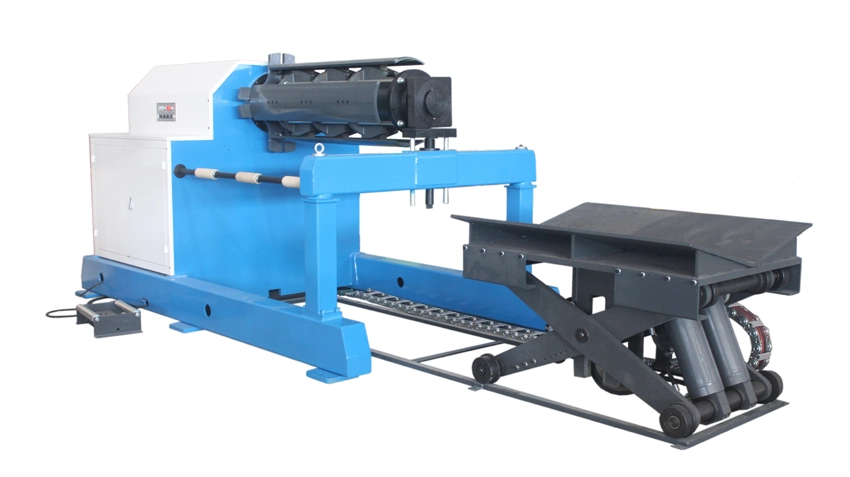

3. Hydraulic Decoilers

Feature hydraulic expansion of the mandrel for fast coil loading/unloading.

Best for handling large, heavy coils and high-volume production lines.

Can be integrated with coil cars or automatic centering systems.

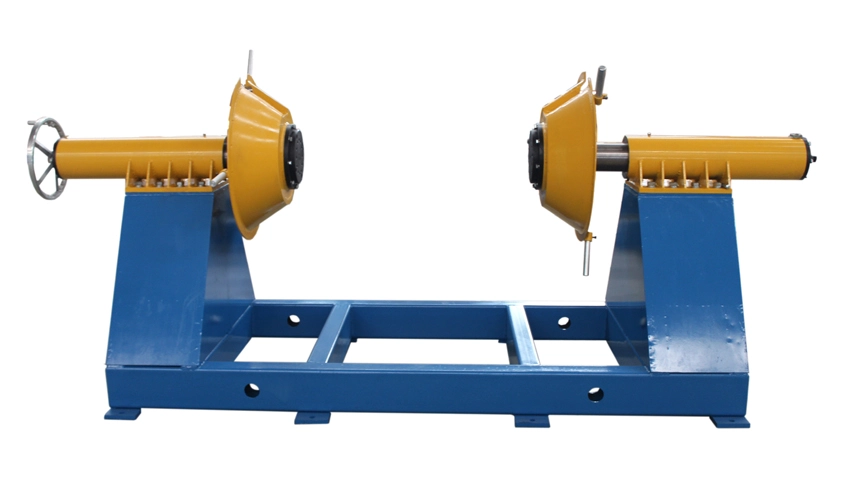

4. Double-Head Decoilers

Two mandrels allow quick coil changeovers, reducing downtime.

Often used in punching or roll forming lines with frequent profile changes.

Improves efficiency in high-mix, low-volume environments.

5. Pallet Decoilers

Designed for lightweight, narrow coils (e.g., strip steel, wires).

Coils rest on a rotating pallet, making them compact and easy to load.

Useful in compact lines or secondary operations.

Each type serves a unique purpose. Understanding your throughput, material size, and automation level will help you make the right choice.

To choose and maintain a decoiler properly, it helps to understand how it works and what its core components do:

● Mandrel

The central shaft where the coil is mounted. Some mandrels are expandable (manually, mechanically, or hydraulically) to grip coils securely from the inside diameter.

● Brake System

Controls the tension and prevents the coil from unspooling too quickly. Options include manual brakes, pneumatic brakes, or servo-controlled tensioning for high-precision feeding.

● Coil Holding Arms / Pressing Arm

Used to stabilize the coil during rotation. Pressing arms are especially helpful in preventing coil “spring out” when uncoiling preloaded coils.

● Drive Motor & Gear Reducer

In motorized decoilers, the motor and reducer set the uncoiling speed and torque, often managed via variable frequency drives (VFDs) or PLCs.

● Induction Sensors

These detect loop height or coil end to trigger feeding, braking, or stop/start operations automatically, ensuring synchronization with downstream equipment.

Together, these components allow for safe, consistent, and automated uncoiling of coils—regardless of thickness or weight.

Keeping your decoiler in peak condition is essential for maximizing uptime and minimizing production risks. Here are key best practices:

● Routine Maintenance

Lubricate bearings, mandrels, and moving parts according to the manufacturer's schedule.

Inspect hydraulic lines, tension systems, and motors for wear or leaks.

Check coil holding arms and safety interlocks regularly.

● Tension Calibration

Over-tensioning can damage material or cause excessive wear on the mandrel.

Use a tension control system or monitor loop sensors to maintain optimal feed rate.

● Safety Protocols

Ensure all guards are in place and safety sensors are operational.

Use coil cars or lifting tools for heavy coil loading—never rely on manual lifting.

Operators should be trained on emergency stops and maintenance lockout/tagout procedures.

● Compliance & Certification

Always verify that your decoiler complies with safety standards like CE, UL, or ISO.

Choose machines with documented quality testing and electrical safety features.

By prioritizing regular maintenance and safety training, you not only extend the life of your decoiler but also ensure the safety of your team and the reliability of your line.

Whether you're upgrading your existing line or planning a new one, selecting the right decoiler is a foundational decision. While performance and compatibility are key, understanding the decoiler price and how it fits into your overall budget is equally important. With the right equipment in place—properly maintained and safely operated—you’re set up for a smoother, more efficient production process from start to finish.

Want help choosing the best decoiler for your specific needs? Let’s connect—I’ll help you find the right fit based on your production goals.